Project Duration: 2023 – present

Other Partners

Project Description

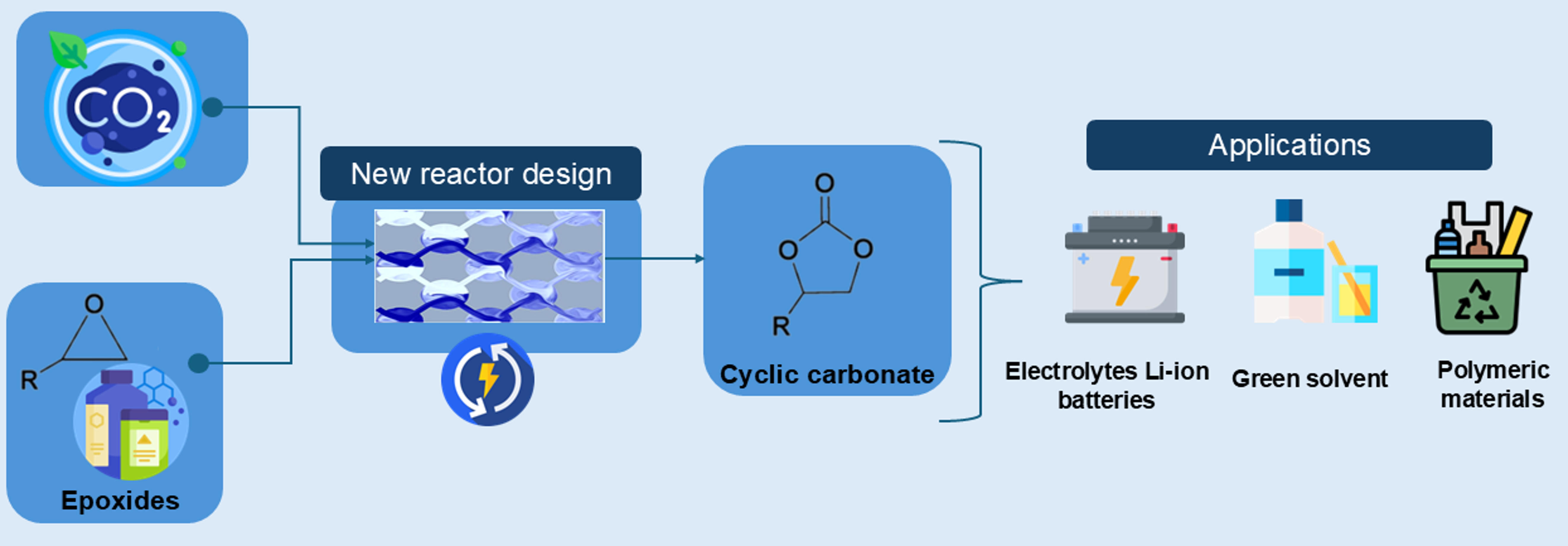

This project aims to develop an innovative and competitive technology for converting CO₂ into cyclic carbonates (CC)—a high-value chemical with diverse applications, including electrolytes for lithium batteries, green solvents, and precursors for polymeric materials. To achieve this, the project focuses on:

•Designing and developing a continuous flow system for CO₂ and epoxide conversion under mild conditions.

•Comparing batch and continuous processes for CO₂ and epoxide cycloaddition through kinetic studies and process simulations.

•Optimizing and benchmarking the process to improve efficiency, scalability, and commercial viability.

Main Outcomes

Development of a prototype for an intensified process to produce CC from CO2 using a continuous-flow reactor able to overcome the gas-liquid mass transfer limitations;

The implementation of the micro-structured reactor is expected to significantly reduce energy consumption and enhance safety by minimizing the risks associated with handling epoxides in batch processes.