“Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.”

xxxx | xxxx

Project Duration: 2021 – present

Type of Project: Internal R&D

Partners

Project Description

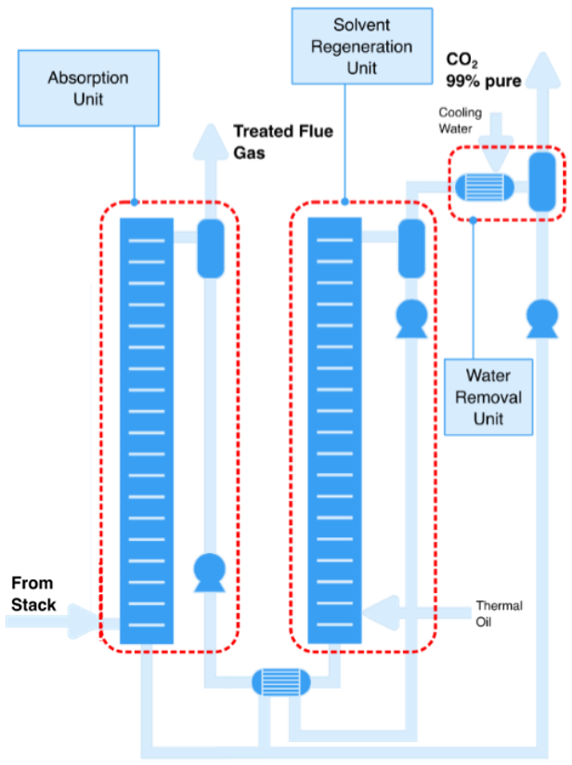

AirPure AGtL captures CO2 through a chemical absorption process involving two stages: flue gases react with a solvent in the absorber to capture CO2, and the CO2-enriched solution is heated in the regenerator to release CO2. This process is continuously recycled for efficient capture and separation. The combination of amine-based solvents and the NET4CO2’s micro reactor enhances absorption efficiency through oscillatory laminar flow, making it effective for CO2 concentrations between 1% and 15%. NET4CO2 achieves mass transfer rates more than 50 times higher than conventional methods.

Main Outcomes

Construction of a Prototype for the Continuous Capture of CO2: Prototype able to treat up to 1 kg/h of flue gas, with CO2 concentrations ranging from 1 – 15%, including solvent regeneration and recirculation, capable of capturing up 80 – 95% of CO2, with a purity over 95%.

Construction of a Pre-Treatment Unit: Direct contact cooler module included for the pre-treatment of real gases, to remove SO2 and NO2 to reduce capture solvent degradation.

Solvent Development: Optimization of solvent formula aiming to reduce energy consumption and environmental footprint.

Construction of Mobile Unit: Unit in a container to operate as an industrial testing unit.

Intellectual Property

European Patent Submission: Patent focusing on the carbon capture based on AGtL technology (Application Number EP24200091.7).