“Our partnership with Net4CO2 to develop a carbon capture pilot in Portugal is progressing according to plan….BA remains dedicated to advancing measures for CO2 capture and sequestration. In pursuit of this goal, we have forged a partnership with Net4CO2, a Portuguese collaborative LAB focused on research and development.”

BA Glass Annual Report

Project Duration: 2022

Client

Other Partners

Project Description

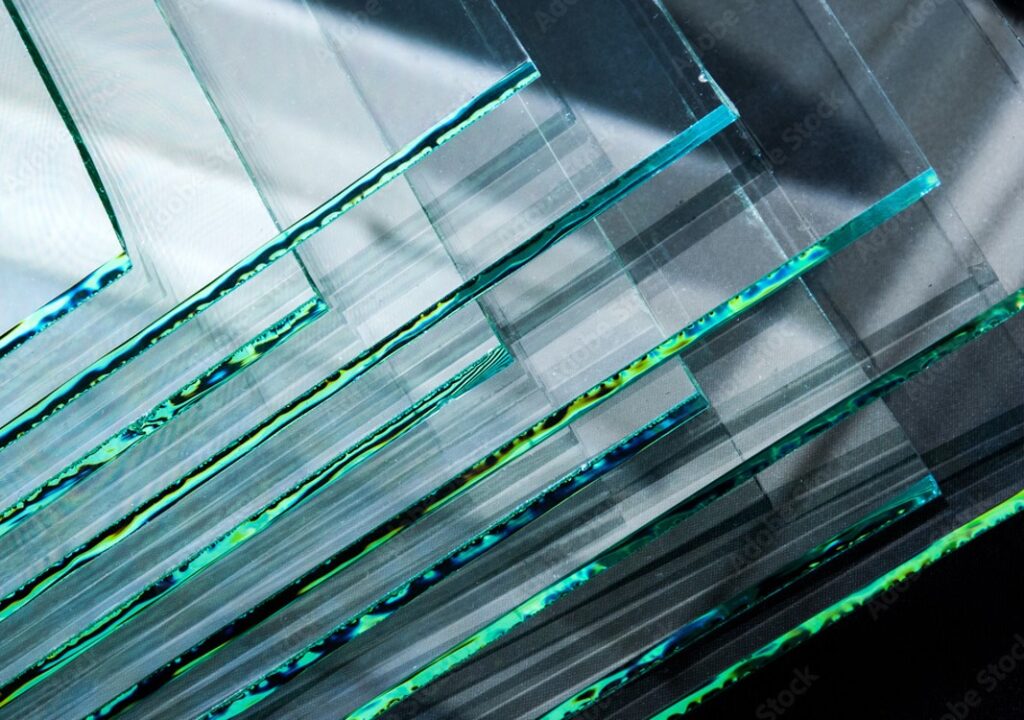

This consulting project aims to develop an advanced multi-physics model capable of accurately simulating the Glass Melting Process within the Furnace at the Avintes facility. The model will integrate thermal and chemical phenomena to provide a holistic representation of furnace operation. Its objective is to serve as a predictive and optimization tool that supports decision-making by evaluating the economic, energy, and environmental impacts of various operating conditions, material inputs, and technological configurations. The model will ultimately enhance process understanding, enable operational efficiency, and support decarbonization efforts aligned with corporate sustainability goals.

Main Outcomes

Comprehensive Multi-Physics Model: A robust, validated simulation tool integrating thermal, fluid flow, combustion, and radiative heat transfer physics to replicate the behavior of the Glass Melting Furnace under real operating conditions.

Operational Optimization Scenarios: Simulation of different operating strategies to identify the most cost-effective and sustainable production setups.

Validation with Real Plant Data: Comparison of model predictions with measured data from the furnace to ensure accuracy and build confidence for future application.

Decision-Support Dashboard: Development of a user-friendly interface for plant operators and engineers to interact with the model and visualize simulation results in real time.

Sensitivity Analysis of Key Parameters: Evaluation of how variations in input conditions influence performance indicators, helping prioritize process improvements.